Colour Measurement of Colourants and Pigments

Quality control and formulation of liquids, pastes, powders, and granules

Colour preferences and pigment development go hand in hand. End users react on latest colour trends and colourant producers are under a permanent pressure to develop new colour shades. Colourant and Pigment manufactures are the starting point for other industries and, therefore, maintaining consistent quality is crucial.

Konica Minolta measuring instruments include a range of powerful colour measurement tools used to accurately and repeatedly meet customer demands and provide a complete solution for colourant and pigment manufacturers regardless the size of the production.

Colour measurement allows organisations to implement data driven process control and quality control procedures that improves output consistency, saves time, waste, and environmental impact.

Whether for internal controls, colour communication with your supply chain, colour matching, or remaking from a database of colours, our software solutions are supported by an experienced team who can help you to accurately specify, produce, and communicate colour, even tracking and calculating with secondary properties. Digital colour and appearance data can be used to expedite the supply process, greatly improving a pigment producer's ability to react to the market by reducing the risks and costs associated with producing, distributing, and maintaining physical standards.

The need for constant innovation and keeping up with the latest colours, while maintaining quality and delivery times, requires a reliable colour management.

Colour measurement, applied when visiting with customers, agreeing specifications with suppliers, in paint and coating development laboratories, benchmarking industry competitors, or reporting for internal quality control programs, can build supply chain relationships based on quality, consistency, and reducing subjectivity from specification and approval.

Our benchtop or portable spectrophotometers are manufactured to the highest standards, to provide you with accuracy and traceability alongside innovative features like a built-in display and operator wizard. Benchtop instruments also offer the greatest application flexibility for either liquid paint or components, or solid pigment samples. A portable spectrophotometer such as the CM-26dG is the perfect accompaniment to the process, allowing operators mobility and flexibility whilst maintaining traceability and industry leading inter model agreement with other instruments in the supply chain.

Benefits

- Drive innovation through professional colour management

- Meet customer's demands and specifications

- Achieve tight tolerances according to respective standards

- Speed up processes and decrease number of corrections

- Strengthen brand identity

- Deliver colour on time and on demand

Instruments

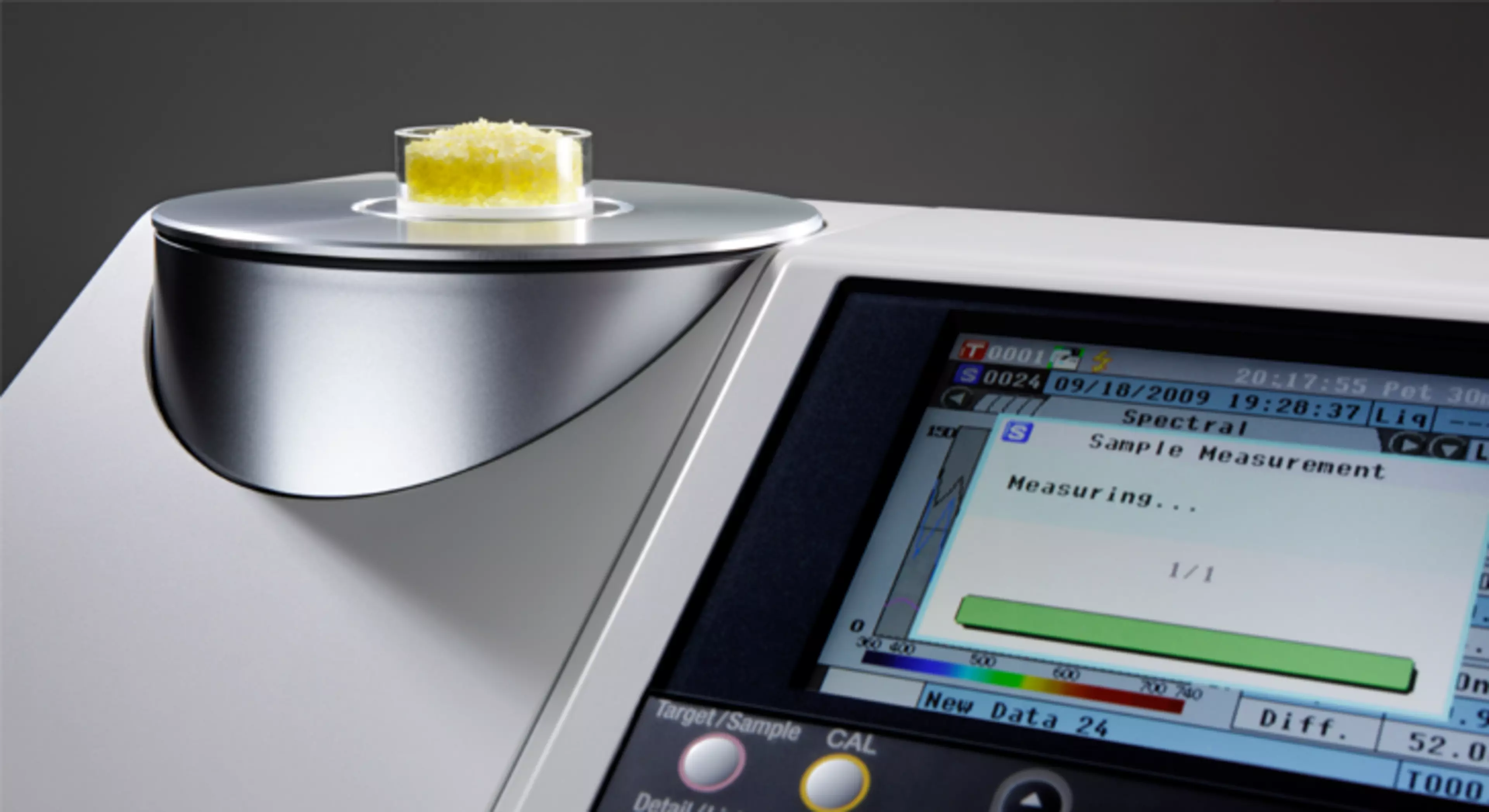

CM-5 Benchtop Spectrophotometer

Benchtop spectrophotometer CM-5 offers the perfect combination of versatility and simplicity, capable of covering a wide range of materials, excelling in user-friendliness and minimal sample preparation time. The operator can freely select between 30, 8 and 3 mm measuring aperture to allow adaption to the sample size.

CM-26dG Portable Spectrophotometer

With its lightweight ergonomic design, optional Bluetooth™ and high-resolution TFT colour display, the CM-26d series is perfectly suited for applications both in the lab and in the field. It features an integrated 60-degree gloss sensor for simultaneous colour and appearance measurement. Designed for usability setting a new standard for fast and accurate data handling.

CM-36dG Benchtop Spectrophotometer

The CM-36dG spectrophotometer is a high-precision and high-reliability benchtop instrument capable of measuring colour either in reflectance or transmittance, and 60° gloss. The spectrophotometer utilises the patented and proven Numerical UV Control (NUVC), unsurpassed technology for UV adjustments when measuring samples that contain optical brighteners.

Applications

Measurement of Pastes, Powders, Granules samples

Measuring areas with 30, 8 and 3 mm allow perfect adaption to the sample size. Pastes, powders, or granules can easily be measured with the optional petri-dish set. The top-port concept allows easy sample positioning: simply place the sample on the measuring port and press the measurement button.

Measurement with CM-26dG

High-precision technology allows users to accurately evaluate colour attributes of various samples, including solids, liquids, powders, pastes, and granules, and identify any inconsistencies immediately in a more efficient and streamlined process. In addition to meeting colour quality standards and consumer expectations, waste is reduced and profits are increased.

Ask our experts