Colour Measurement of Recyclates

Control colour quality of your recycled materials and formulate colours accurately, even when integrating recyclates. Meet your customer's demands while reducing plastic waste and boosting environmental credentials.

The worldwide production of plastic products has been increasing for decades and this trend is expected to continue. In parallel, the amount of plastic waste generated each year grows dramatically.

With increasing awareness of environmental preservation, plastic recycling is one of the most significant initiatives for our society. Based on the EU Packaging and Packaging Waste Regulation (PPWR), all plastic packaging materials should be recyclable in an economically viable way by 2030. The plastic industry has been making extensive efforts to develop technologies for reducing plastic waste and better sorting and reusing plastics. Modern Colour measurement technology utilised in the plastic supply chain is supported by formulation software that is developed with these challenges in mind. The technology on this page will help customers in the recycling industry to more cost and time effectively sort, use, report or sell recycled product.

Recyclates are usually a mixture of different plastic types, with inhomogeneous colours and may even be contaminated by foreign objects. All this has a significant impact on recyclate's quality, value and ease of use. Colour is one of the most important factors in the quality and economical viability of plastic recyclates.

As a solution provider to the plastic industry, Konica Minolta measuring instruments offer customers accurate and traceable colour measurement solutions for sorting, characterising, and reusing recycled polymers. Our experts can help you establish systems for minimising waste, minimising losses, and improving your tolerances. This can be everything from characterising the colour of inhomogeneous plastic samples or products, to helping companies maintain colour accuracy whilst integrating their own production waste or a percentage of recycled polymers. The appetite for recycled plastics is huge and the possibilities for producing quality products are only just beginning to be explored.

Recyclates represents a huge commercial opportunity for the sector in improving products and processes, and in offering customers products that utilise recycled plastics.

Konica Minolta has a dedicated team of experts responsible for implementing, training, optimising, and customising systems for colour formulation and digital colour data communication. Our experts can help your teams to establish digital colour standards and colour difference tolerances that you can share with your supply chain partners. You can leverage the experience of our application teams to quickly establish repeatable, best-practice processes for colour and appearance measurement and control.

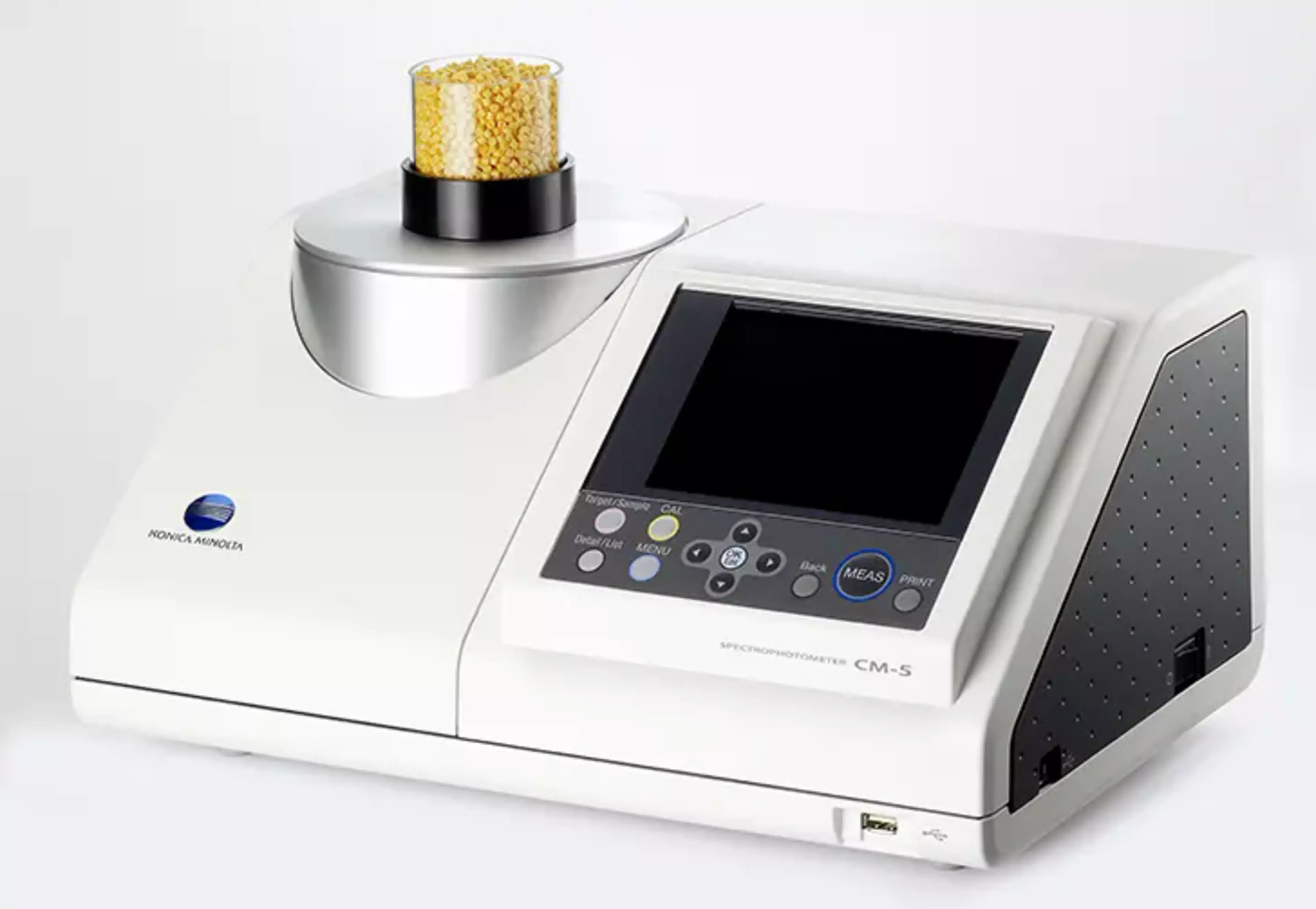

Konica Minolta benchtop spectrophotometers are versatile, accurate, and traceable. By measuring accurate and repeatable colour data for regrind, the industry can improve the formulation of recycled plastics and tighten production tolerances for the products that they produce.

Combining traceable colour data with a Computer Colour Matching System will enable colour producers to repeatably quickly and economically increase their use of recycled product without compromising on colour accuracy or quality, even accounting for variability in the recycled materials used in each batch.

Konica Minolta group company SPECIM is at the forefront of hyperspectral vision systems, providing the recycling industry with inline solutions for identifying and sorting plastic products of different types and colours. Improving the quality of sorting within the recycling process is a crucial step in improving the possibilities of the recycled product.

Benefits

- Classify recyclates faster and more consistently with objective colour data (supporting sorting decisions and acceptance/rejection thresholds).

- Increase recycled content without sacrificing appearance by controlling colour variability before blending and compounding.

- Reduce pigment/additive trial-and-error in compounding with data-driven colour matching, cutting pigment waste and rework.

Instruments

Chroma meter / Colorimeter CR-5

Versatile benchtop colorimeter for measuring the colour of solid, powder, and liquid samples in either reflectance or transmittance mode. It features a top port, colour display, and standalone or PC operation. Its user friendly firmware facilitates setting of colour differences and tolerances.

Light Cabinets for Controlled Viewing

Light Cabinets in various configurations for visual assessment of colour using LED/Hybrid technology illumination. Offers additional options for custom light sources and has a lamp lifetime 10 times conventional lamp systems reducing calibration and replacement costs.

Applications

Case Study: Colour measurement for recyclates with CM-5

As a recycling specialist, ECOPOLYMERS GmbH brings used plastic back into the cycle. Together with partner companies, the company processes more than 30,000 tonnes of PET flakes into high-purity PET pellets every year. These unmixed products are a sought-after raw material worldwide, especially for the food industry.

Discover how ECOPOLUMERS GmbH successfully integrated colour measuring devices in their quality control process.

Case Study: Evaluation of colour quality for recycled plastics

Facing challenges to manufacture preforms for PET bottles from recycled pellets, discover how the company Altech New Materials Co. has implemented a colour measuring device a several stages of their QC process.

From inspection of the recycled pellets until the inspection of the finished product in preform, ensure a reliable colour quality standard for recycled pellets with the CR-5 benchtop colorimeter.

Ask our experts