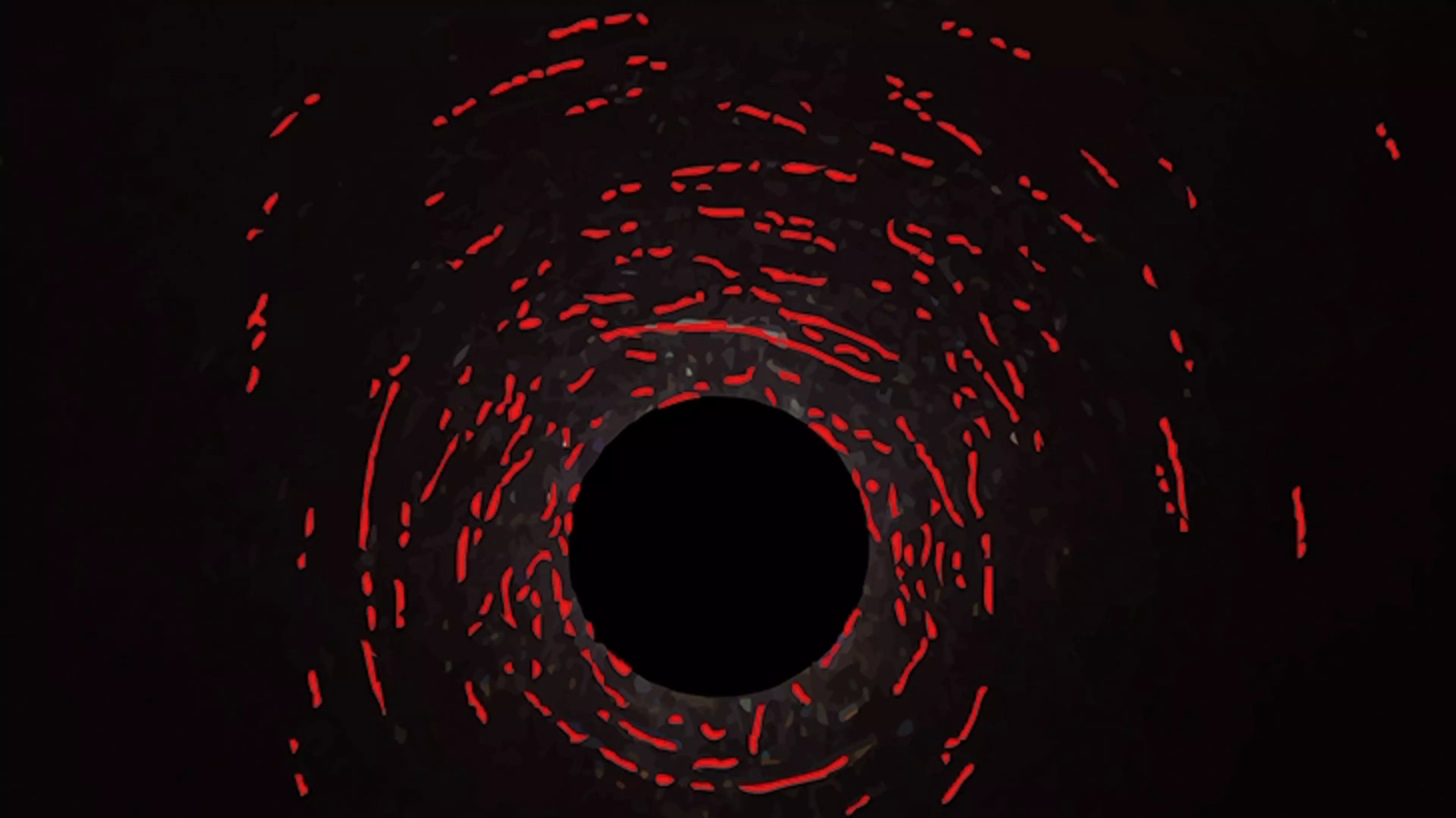

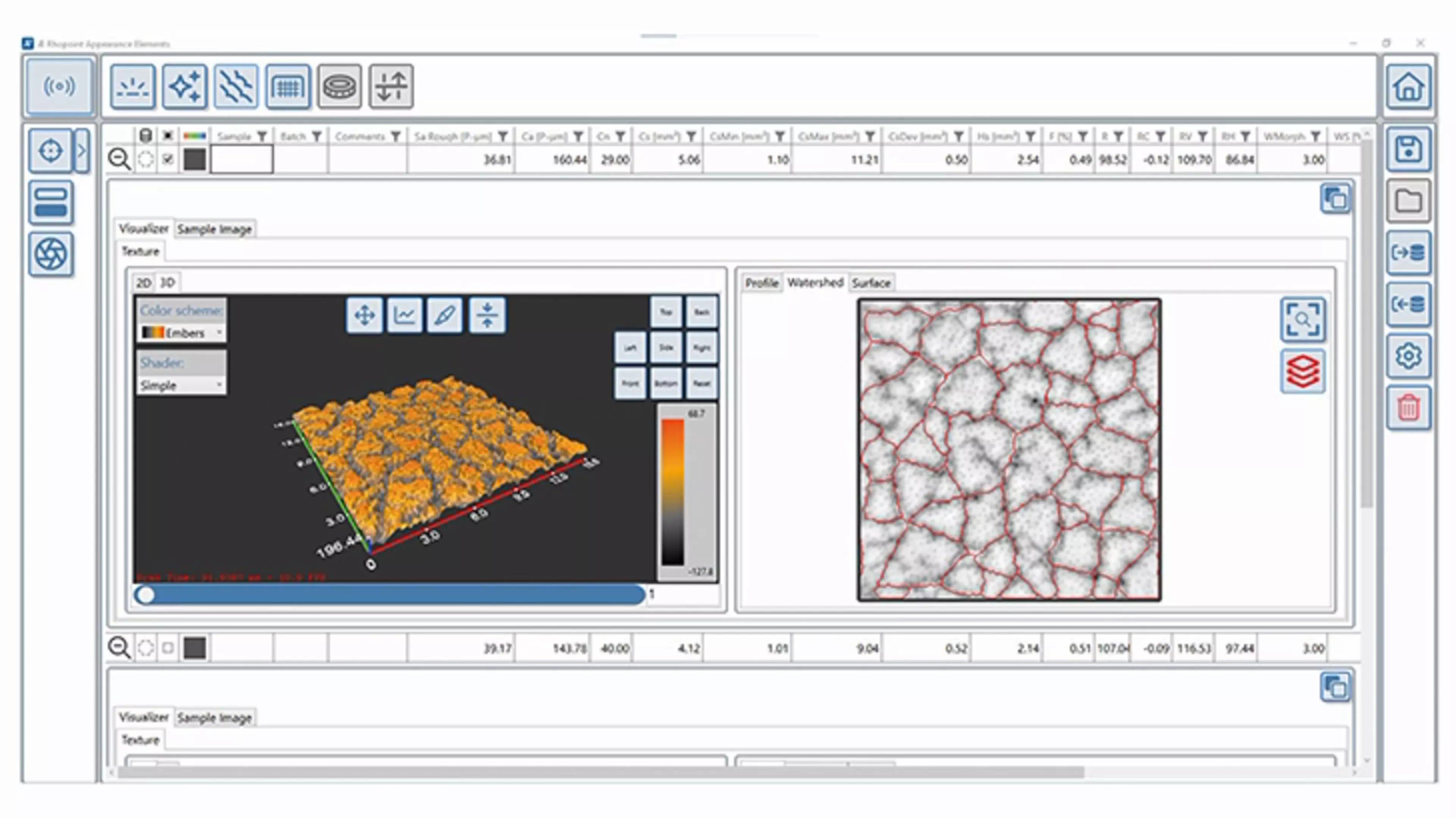

The Rhopoint Aesthetix® delivers the most comprehensive quantification of surface appearance—mirroring how surfaces are perceived by the human eye. Whether it’s gloss, colour, texture, or surface structure, Aesthetix® uses cutting-edge, perception-based metrics co-developed with academic and industrial partners to provide a level of insight unmatched by traditional gloss meters.

It allows the operator to objectively define and control visual appearance for all kinds of surfaces helping to optimize quality correct processes and ultimately improve consumer appeal.

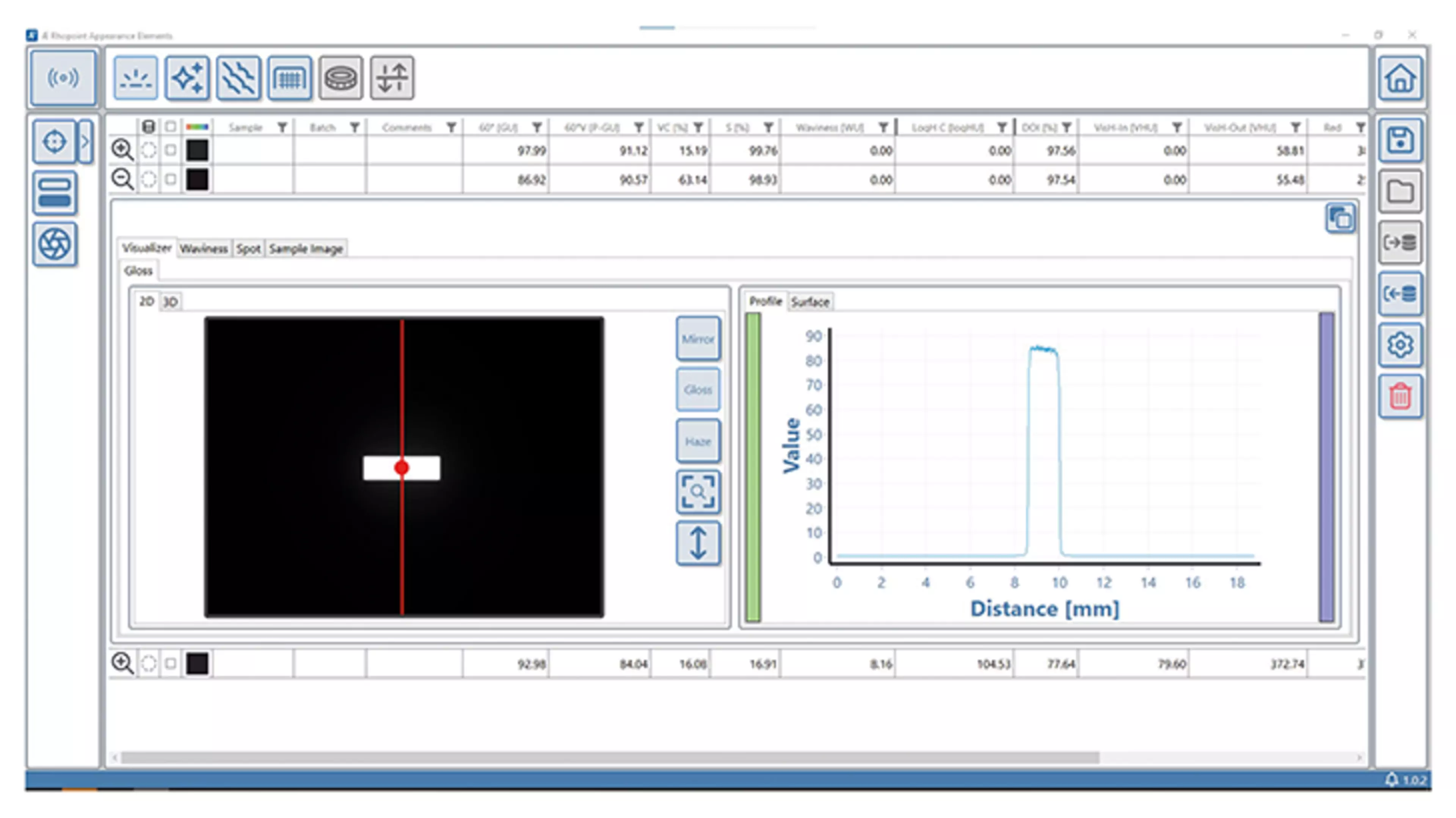

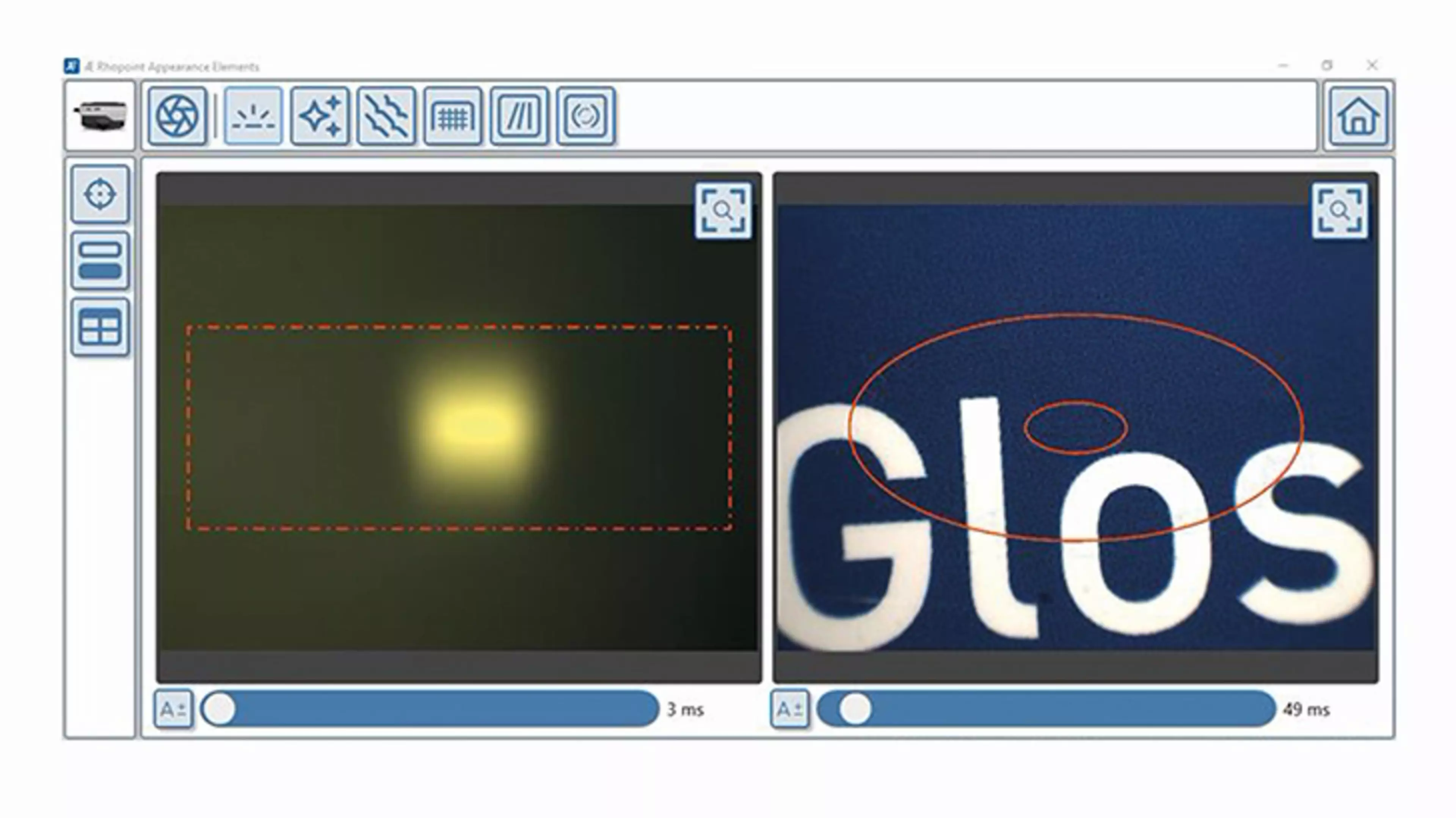

Aesthetix® uses cutting-edge optics to combine Technical measurement data with perception-based algorithms that replicate how humans perceive surface quality.

Use Aesthetix® in:

- R&D labs for appearance optimization

- QA workflows for pass/fail decisions

- Automated robot cells for in-line inspection

- Portable applications via tablet control