Providing Stability and Reassurance to Users Who Demand Superior Quality

Konica Minolta to launch the new flagship model CM-3700A Plus benchtop spectrophotometer, replacing the highly evaluated CM-3700A spectrophotometer widely used as the reference standard instrument for measuring colours.

Konica Minolta, Inc. (Konica Minolta) today announced that the Company will launch the CM-3700A Plus, the flagship spectrophotometer model.

In quality control in the manufacturing industry, colour management using measuring instruments is crucial. Due to their superb reliability and multifunctionality, Konica Minolta’s colorimeters are used for various applications, including quality control, production, and R&D, in industries where colour measurement and management are required, such as automobiles, electrical equipment, smartphones, cosmetics, paints, plastics, building materials, and textiles.

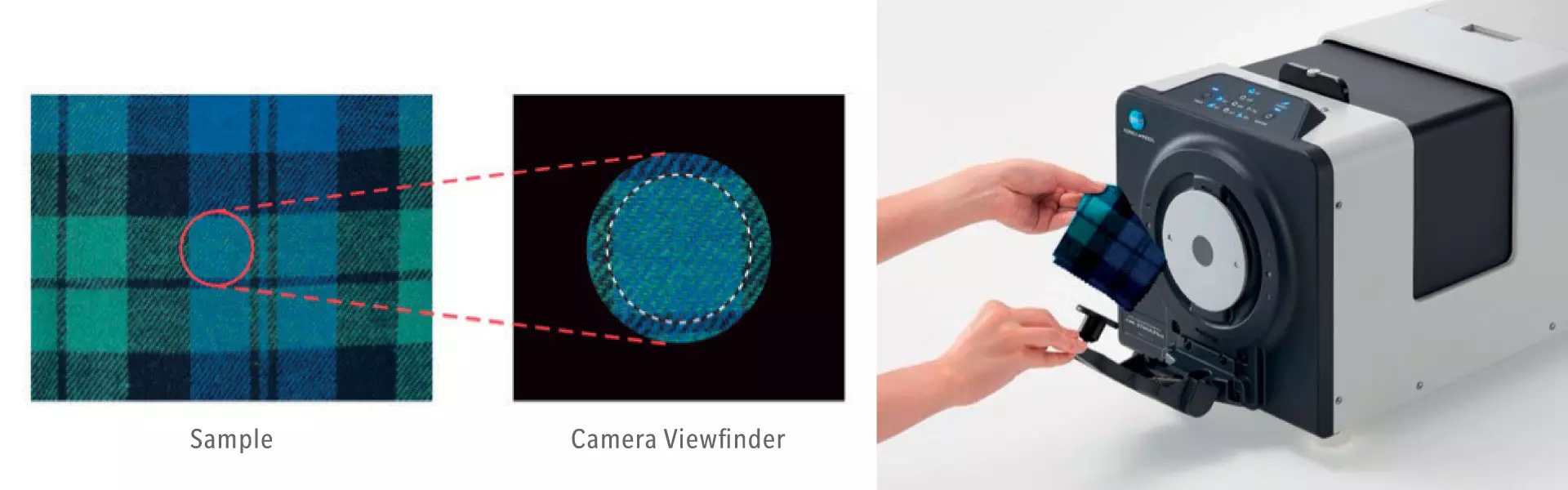

The CM-3700A Plus is the successor model to the CM-3700A that has been highly evaluated and widely used by many companies globally as the reference standard instrument for measuring the colours of objects. This new flagship spectrophotometer model delivers high accuracy and reliability; world-class accuracy has been realised by harnessing Konica Minolta’s optical technologies. The CM-3700A Plus also comes with new functions, such as an easy-to-position camera viewfinder and a sample thermometer to measure the temperature concurrently with colours, thereby realising more rigorous colour management. Given that it will be used as a reference standard instrument in colour management, the CM-3700A Plus is designed to ensure high compatibility with the conventional model and stably produce reliable measurement values over the long term by using highly durable parts, thereby helping to improve product quality in manufacturing.

Values Provided by the CM-3700A Plus Spectrophotometer

Highly accurate measurement

The CM-3700A Plus features significantly improved repeatability(*1) of black, which is particularly difficult to measure with high accuracy, compared to the conventional model. Because differences in measurement values between instruments are exceedingly small (inter-instrument agreement is very high) at ΔE*ab 0.08 or less(*2), the CM-3700A Plus is advantageous when using multiple instruments or instruments at multiple locations across the supply chain. Data compatibility with the conventional model CM-3700A enables the continued use of measurement data that has previously been accumulated. This new model also ensures high durability in terms of temperature change and aged deterioration by using a polychromator unit housing made of stainless steel.

Improved operability and convenience

Functionality and software for high reliability

Higher measurement efficiency and advanced colour management

The CM-3700A Plus enables the concurrent measurement of SCI and SCE(*4), almost halving the measurement time compared to the conventional model. Equipped with an environmental thermo-hygrometer and a sample thermometer, this new model enables checking and recording of the temperature and humidity and sample surface temperature(*5) of the measurement environment concurrently with colour measurement.

Reassuring services

The CM-3700A Plus is manufactured in Japan under a consistent quality control system. It is also equipped with a WAA (Wavelength Analysis & Adjustment) function, which compensates for wavelength shifts in measurement values due to external factors, including impacts during use and changes in ambient temperature. Together with annual calibration and maintenance, it offers a sense of reassurance and high accuracy.

Colour data management using the SpectraMagic™ NX2 colour data software

The SpectraMagic™ NX2(*6) colour data software enables colour management and data classification using various colour indices and graphs, and communication with business partners using colour values. In addition, with a premium license of Ver. 1.4 or later it is possible to monitor the status of instruments using the daily inspection application, which is a new function.

*1: Repeatability refers to the measurement error when the same specimen is measured repeatedly under the same conditions. It is an index for measurement accuracy. The lower the value, the higher the reliability of measurement values.

*2: An average for 12 BCRA Series II colour tiles.

*3: For connection with a PC, SpectraMagic™ NX2 Ver. 1.5, software which is separately sold, is required.

*4: SCI: Abbreviation for “Specular Component Included.” In this measurement method, specularly reflected light is included in the diffused illumination. The colours of materials are evaluated regardless of the surface condition.

SCE: Abbreviation for “Specular Component Excluded.” In this measurement method, only diffuse reflected light is measured. Colours close to those of visual observation are evaluated.

*5: The sample temperature is measured only during reflectance measurements.

*6: SpectraMagic™ NX2 is separately sold software.