Why do you need regular inspections?

Just as no matter how much we humans sport, our bodies will become worn-out over time, no matter how high-performance a product is, it is inevitable that it will deteriorate due to prolonged use. There are various factors that cause changes in performance depending on the usage environment and frequency of use at the installation site.

Therefore, it is recommended to perform regular inspections to maintain the product hardware with high accuracy at all times and to prevent sudden defects.

Comparison of the internal state of the integrating sphere unit

The figure below is a comparative example of the usage state of the inside of the integrating sphere unit of the spectrophotometer (the part that produces uniform light irradiated on the measured sample).

If you continue to use the unit without inspecting it, there is a risk that the inside will be in a state of use as shown in the figure below, and the measured value may deviate from the specifications, and it may be necessary to replace the unit parts.

Like vehicle inspections to maintain safety and security, measuring equipment also requires regular inspection and maintenance.

Maintain high precision at all times

Due to the poor operating environment and continued harsh use, dust and dust accumulation and fading occur in the optical system of the instrument, making it impossible to measure with high accuracy. Although deterioration of components is inevitable over time, accurate measurements can be demonstrated and maintained by appropriate adjustments according to the condition of the equipment.

* During periodic inspections, the condition of the equipment is checked and the measured values are calibrated (adjusted).

Prevent sudden failures

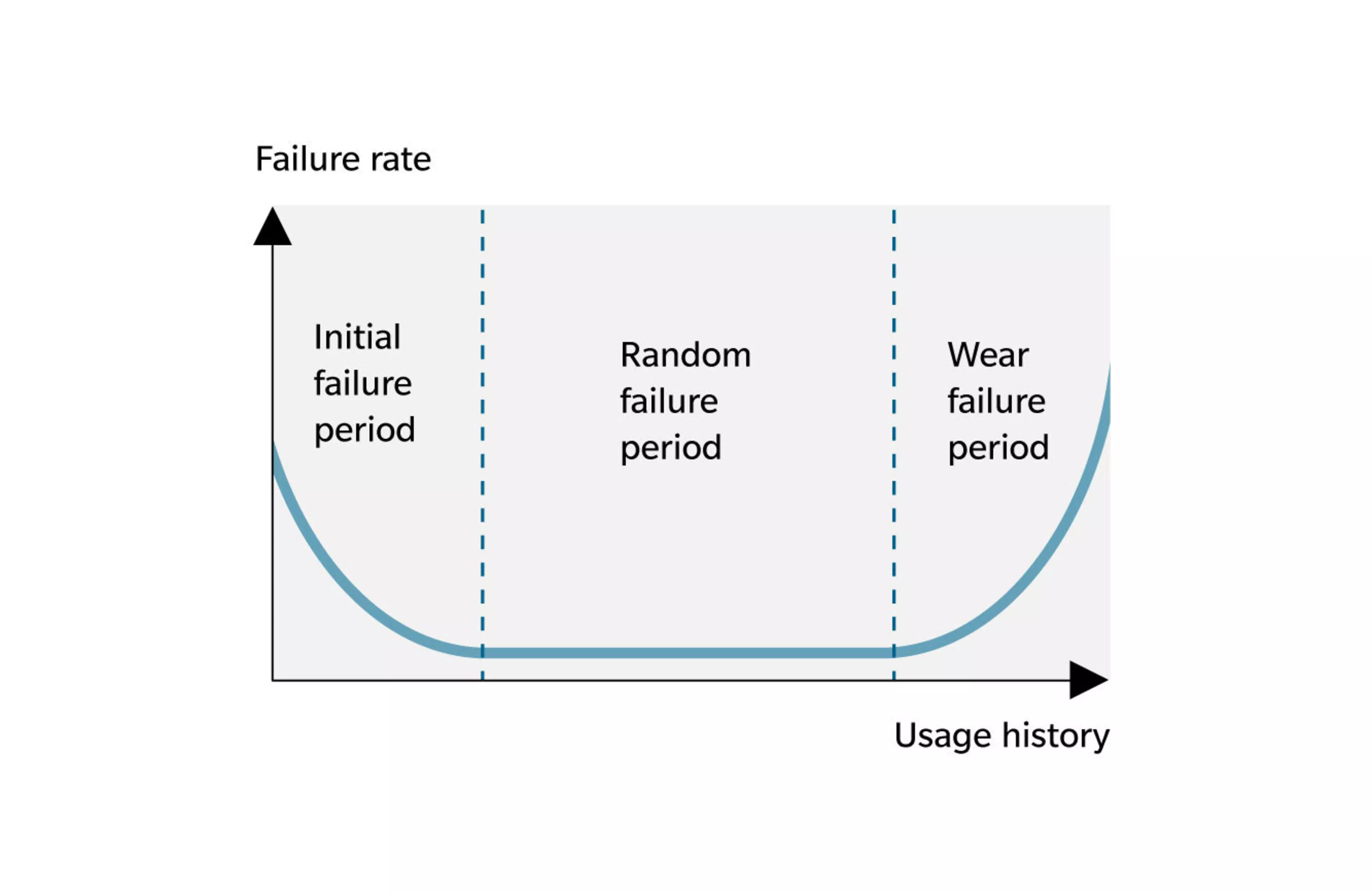

As a general concept, the rate at which failures occur (failure rate) can be divided into three periods, as shown in the figure on the right.

The "wear and tear period" is the period when a failure occurs due to wear or deterioration of parts over use, and depending on the usage conditions and environment, if regular inspections are not performed, the timing may be premature, sudden failures may occur, or expensive unit parts may need to be replaced.

Preventive maintenance is carried out by regular inspections and cleaning and replacing deteriorated and worn parts.