Colour Measurement of Powdered Chemicals Pellets and Granules

Benchtop and portable spectrophotometers for the repeatable colour measurement of chemical powders and pastes.

Whether or not colour is a primary characteristic, colour measurement is used as a tool for quality and process control tool for the chemical industry. Checking the depth of black or the whiteness of whites at goods-in can help companies to better predict the end product, improving consistency and helping to simplify processes.

Konica Minolta Measuring Instruments can be used to repeatably measure the colour of all manner of compounds throughout processing, using purpose-built accessories to aid in repeatable sample presentation for powder and granular samples. Driven by our long heritage in optical excellence and commitment to quality, our instruments feature industry leading inter instrument agreement for communicating and sharing colour data repeatably and traceably.

Our instruments and software are easy to use whilst providing vital colour and colour difference data to operators in development laboratories, in production, or in quality control. Whether used for goods in, development, process control, or quality control, implementing colour data and colour communication can help optimise processes. Our experts can help you to establish a system that will ultimately reduce waste, whether this is by improving communication and tolerances with suppliers, spotting production issues that cause deviations early and being able to cost effectively correct them, or even removing some subjectivity from QC processes.

Specifying, agreeing to deliver, and reporting colour is a USP that builds trust with customers and helps to protect and grow relationships with your customers.

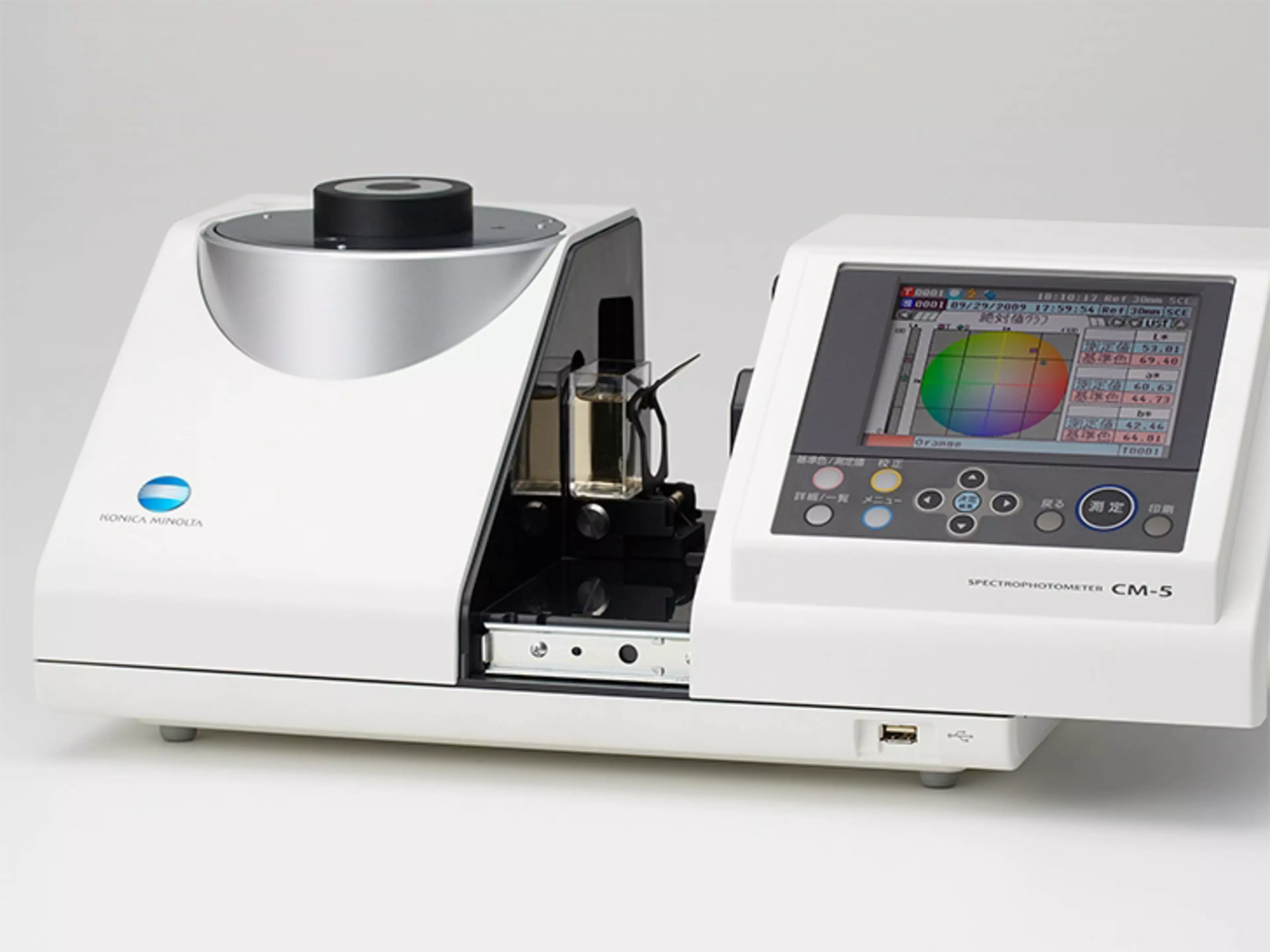

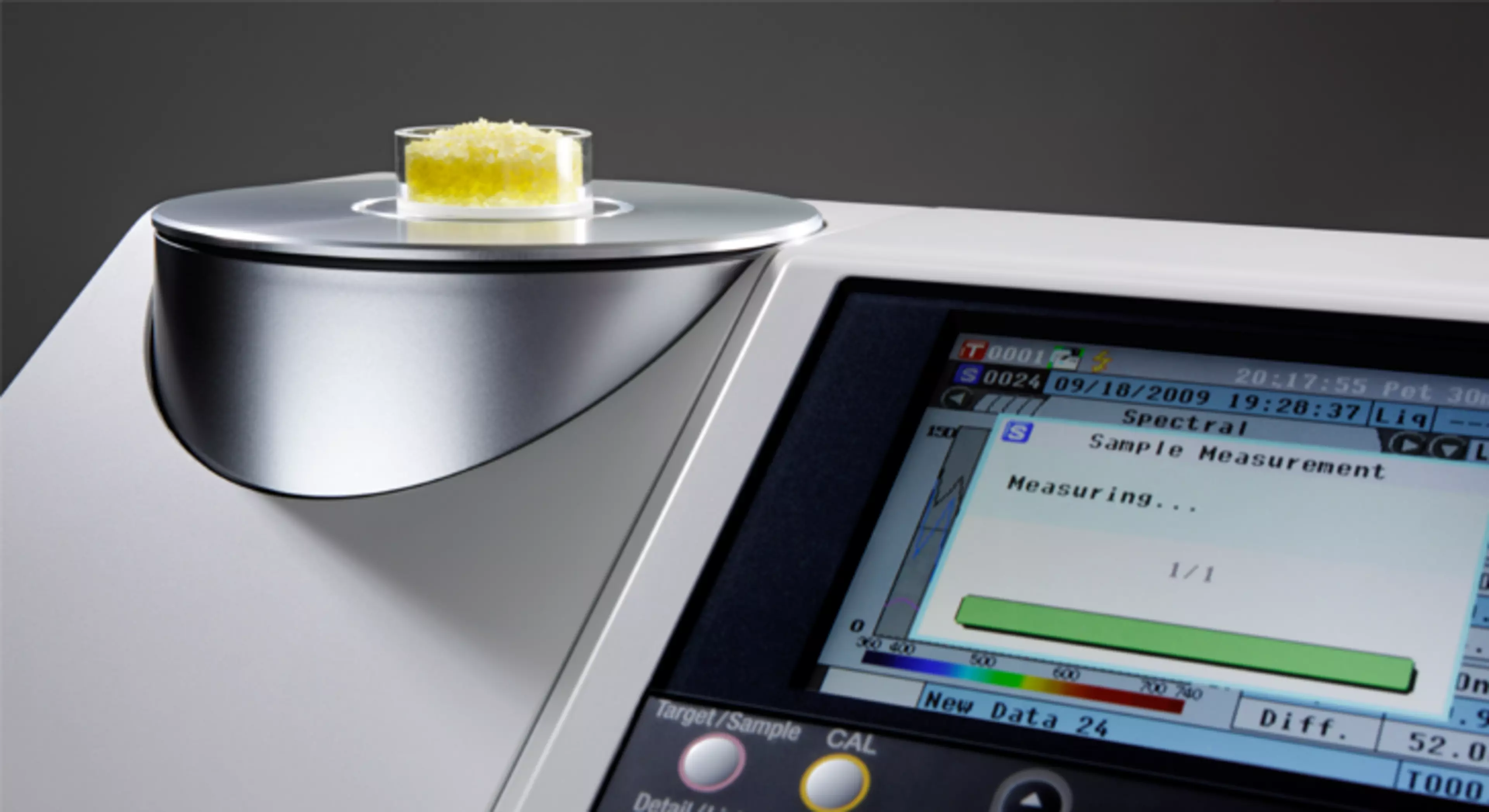

Our versatile benchtop spectrophotometers offer laboratories solutions for measuring virtually all substrates from powders or granules in petri dishes, to liquids in cuvettes. Whilst most applications in this field will be best served by the larger aperture of a benchtop instrument, our range of solutions also includes more portable solutions should your process require. Our experienced teams can recommend a solution, and our extensive service network can ensure that your instruments are maintained and traceable throughout their life.

Benefits

Improve consistency of end product

Reduce waste and out of spec product

Communicate colour accurately and repeatably with suppliers and customers

Integrate colour data to save time throughout development, from corrections to approvals

Instruments

Applications

Measurement of Powders at Goods-in

The CM-5 benchtop spectrophotometer, with built-in display and operator wizard, can provide a simple but accurate system for measuring products at goods-in. This may allow the operator to validate against an agreed specification or to bin different batches, according to their colour standard to improve certainty of the final product.

Measurement of the Whitest Whites

Utilising the CM-36dGV and the SpectraMagic™ NX2 software, a producer can measure finished products such as Titanium Dioxide, accurately and traceably validating its whiteness, generating statistical data across one or more batches, and producing reports for customers.

Ask our experts