Precision Inside Out / Elevate interior car quality with Vision Systems

Automotive Parts Vision Inspection for Doors and Panels

- How satisfied are you with the reliability of your current inspection system?

- How to improve quality and productivity by implementing an automated inspection system?

Customer Challenges

Ensuring consistent and effective Quality Control

At its core, manufacturing sites aim to consistently produce products that effectively meet customer specifications / expectations, time, and cost . Optimised processes identify out-of-specification (OOS) production as early as possible to take corrective action with quality checks, maximising profitability and eliminating unnecessary waste. Modern systems must prevent OOS product from reaching the customer, helping avoid any financial penalties and damage to supply chain relationships.

"Aside from wasted time and components, OOS deliveries can carry financial penalties and jeopardise supply chain relationships."

Improving efficiency of the manufacturing process

To maintain the right balance between high quality and cost, improving the efficiency and productivity of the manufacturing process is important to remain competitive. Process efficiencies need to be addressed by optimising production lines, improving work processes, and eliminating waste.

“To remain competitive, businesses must focus on optimizing production lines, improving work processes, and eliminating waste.”

Overcoming labour shortages

Manufacturing is a labour-intensive industry and labour shortages are a challenge. The decline in the number of young workers and the ageing of the workforce make it difficult to secure an adequate workforce.

“The manufacturing industry faces a challenge due to labour shortages.”

Customer benefits provided by Eines

Improved quality and reliability

Automated inspection systems provided by Eines can improve the accuracy of quality inspections by standardising and automating inspection tasks, without relying on the skill and knowledge level of the operator. With this, you can prevent the outflow of defective products and improve reliability of your final product. It also reduces rework time due to human error.

Increased productivity

Automation is expected to reduce work time and increase work efficiency. This increases production capacity per hour, e.g. by reducing rework. In addition, large amounts of data can be collected and analysed quickly and accurately.

Reduced work time

Automation reduces the amount of time spent on manual tasks. Human resources can be devoted to more sophisticated tasks that cannot be automated, thus adding further value.

Solution provided by Eines

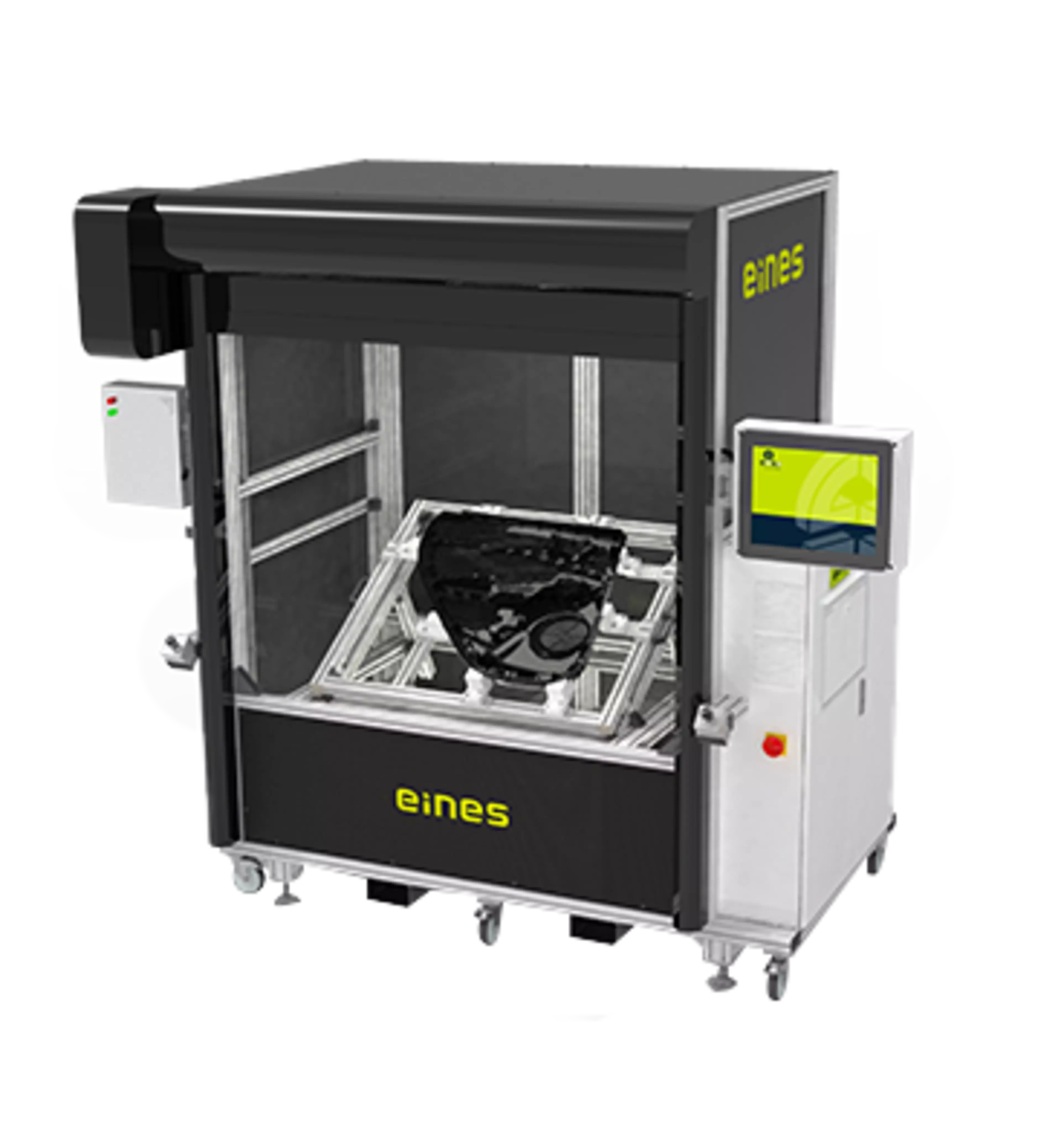

Eines End-on-line (EOL) Station can detect the presence and/or absence of components and surface anomalies such as scratches & dents. Moreover, it is capable of performing colour detection, stitching colour and trend analysis.

Interested to learn more about the different vision inspection systems from Eines?

- Automatic door panel inspection system

- Automatic headliner inspection system

- Automatic instrument panel inspection system

- Automatic tunnel-type inspection system

Contact us directly via the button below and you will receive the detailed brochure.

You can also have a sneak preview of the solution clicking on the below image and watch the demo video.