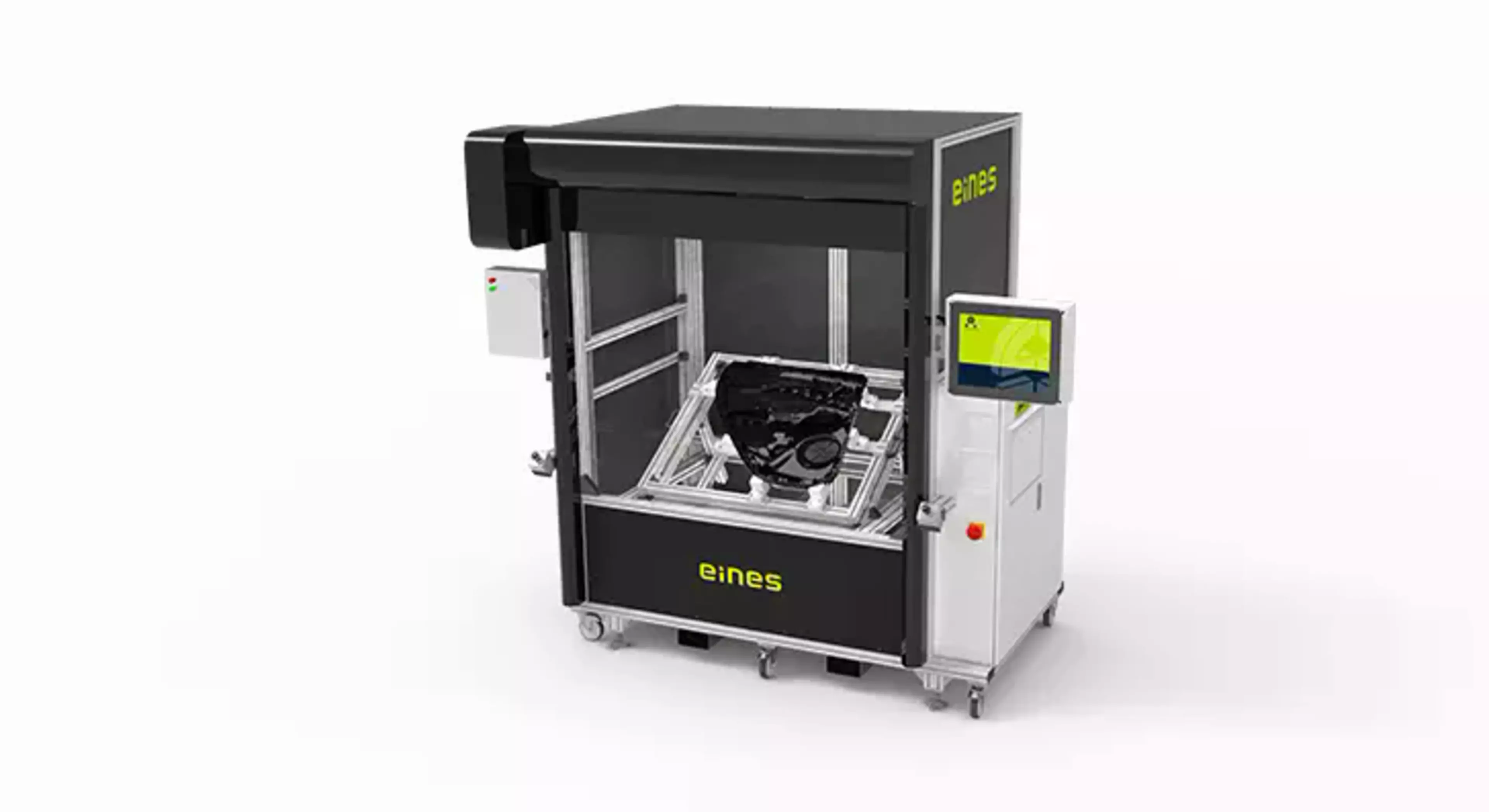

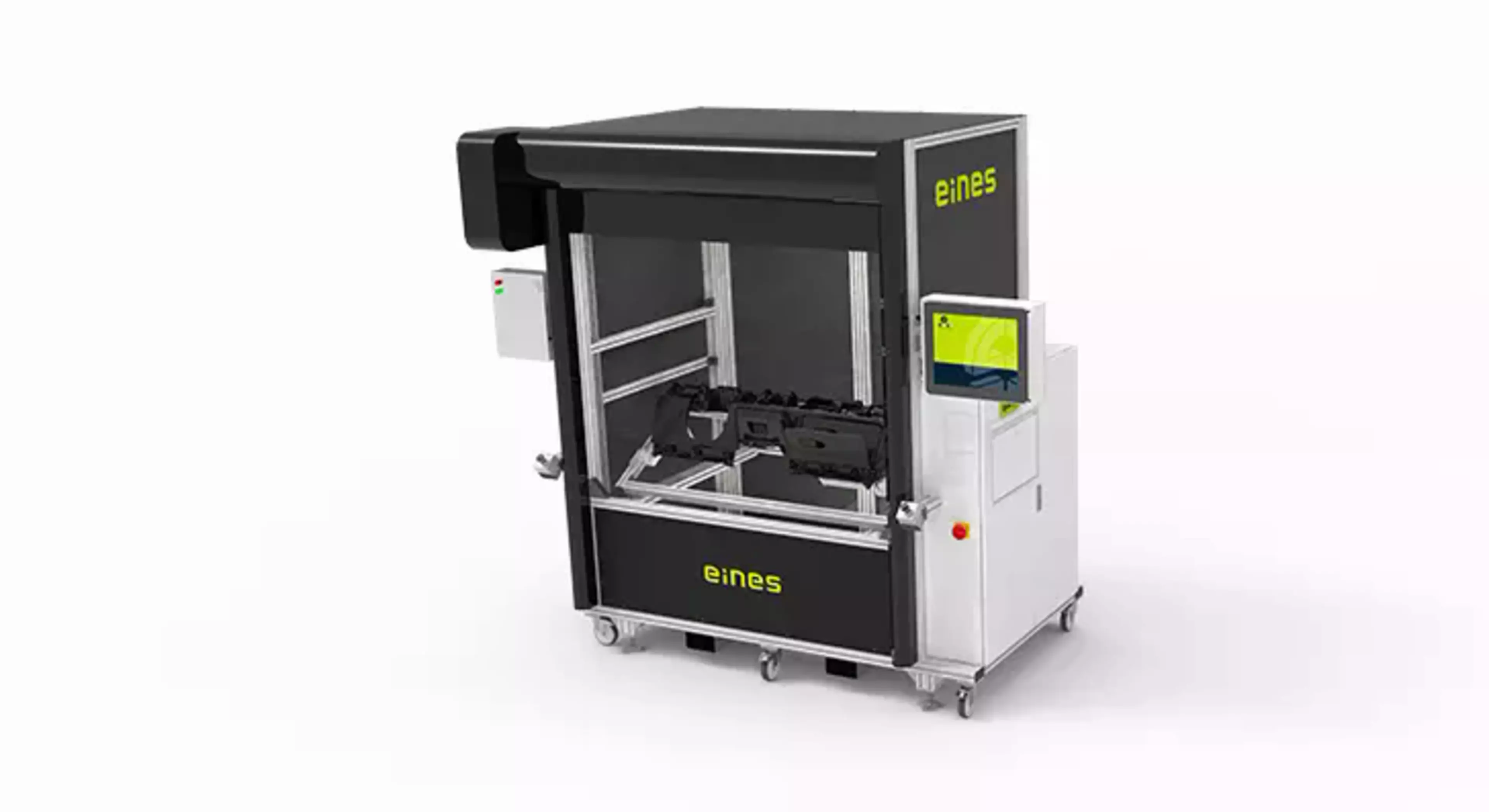

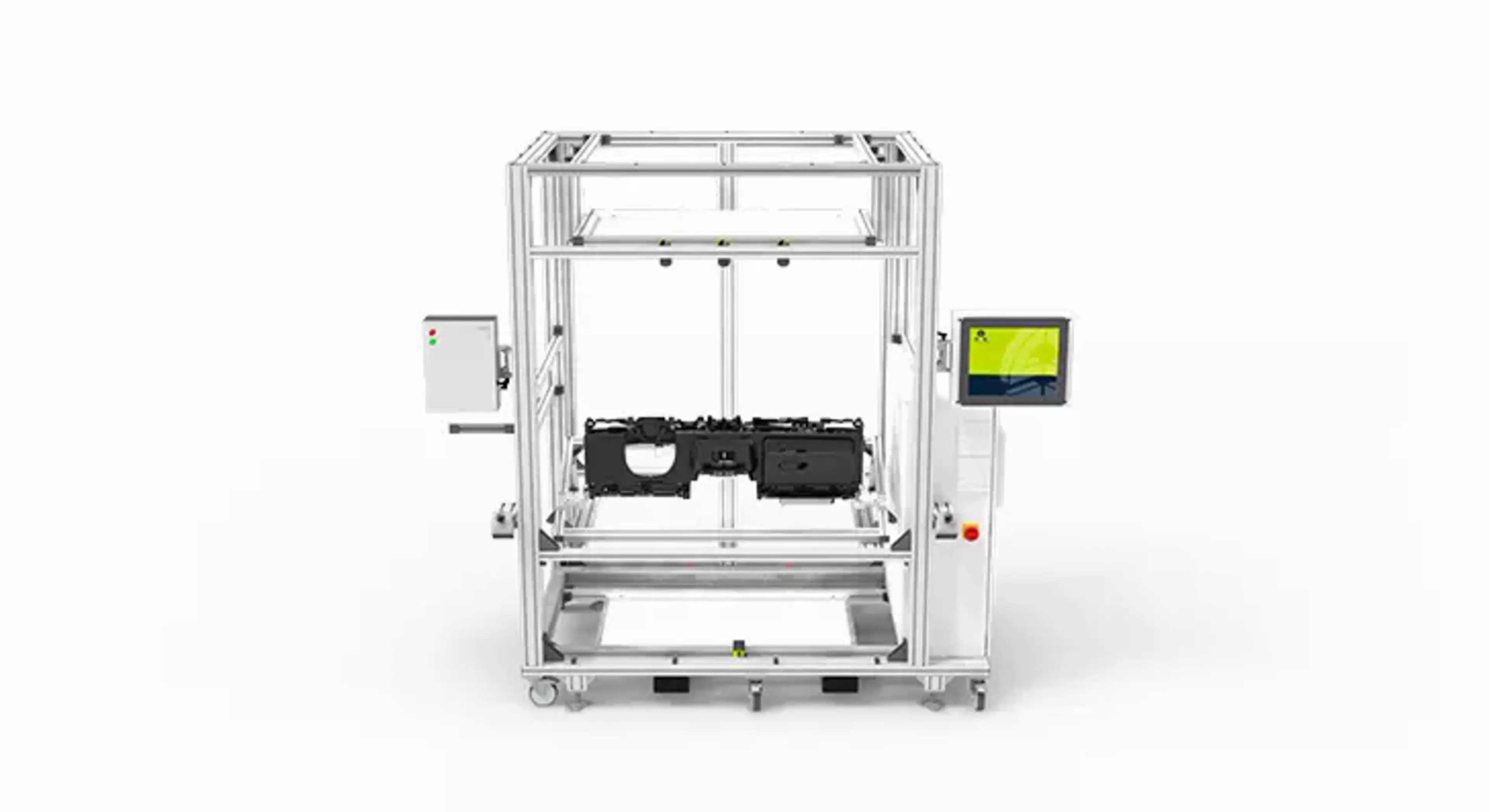

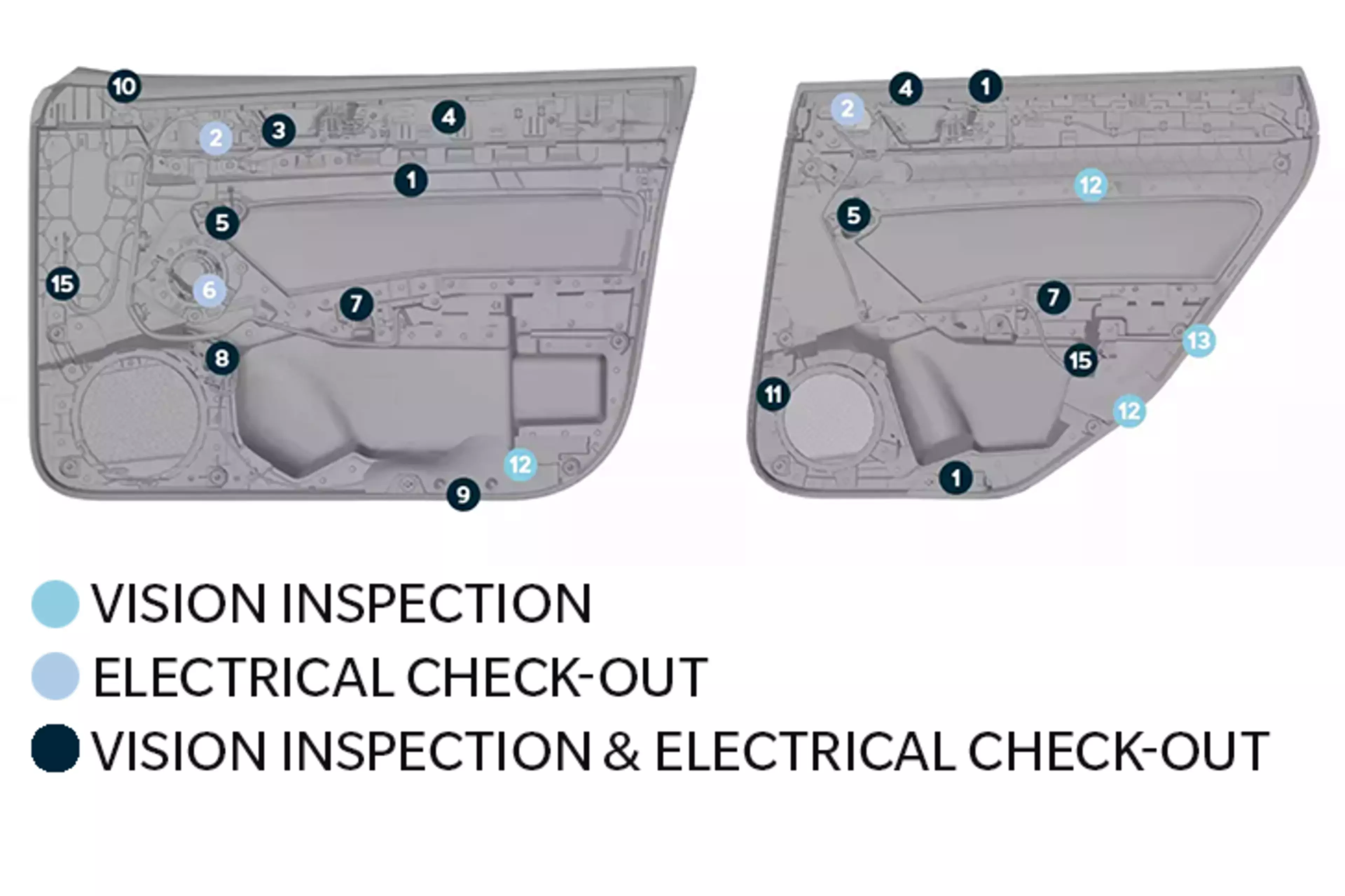

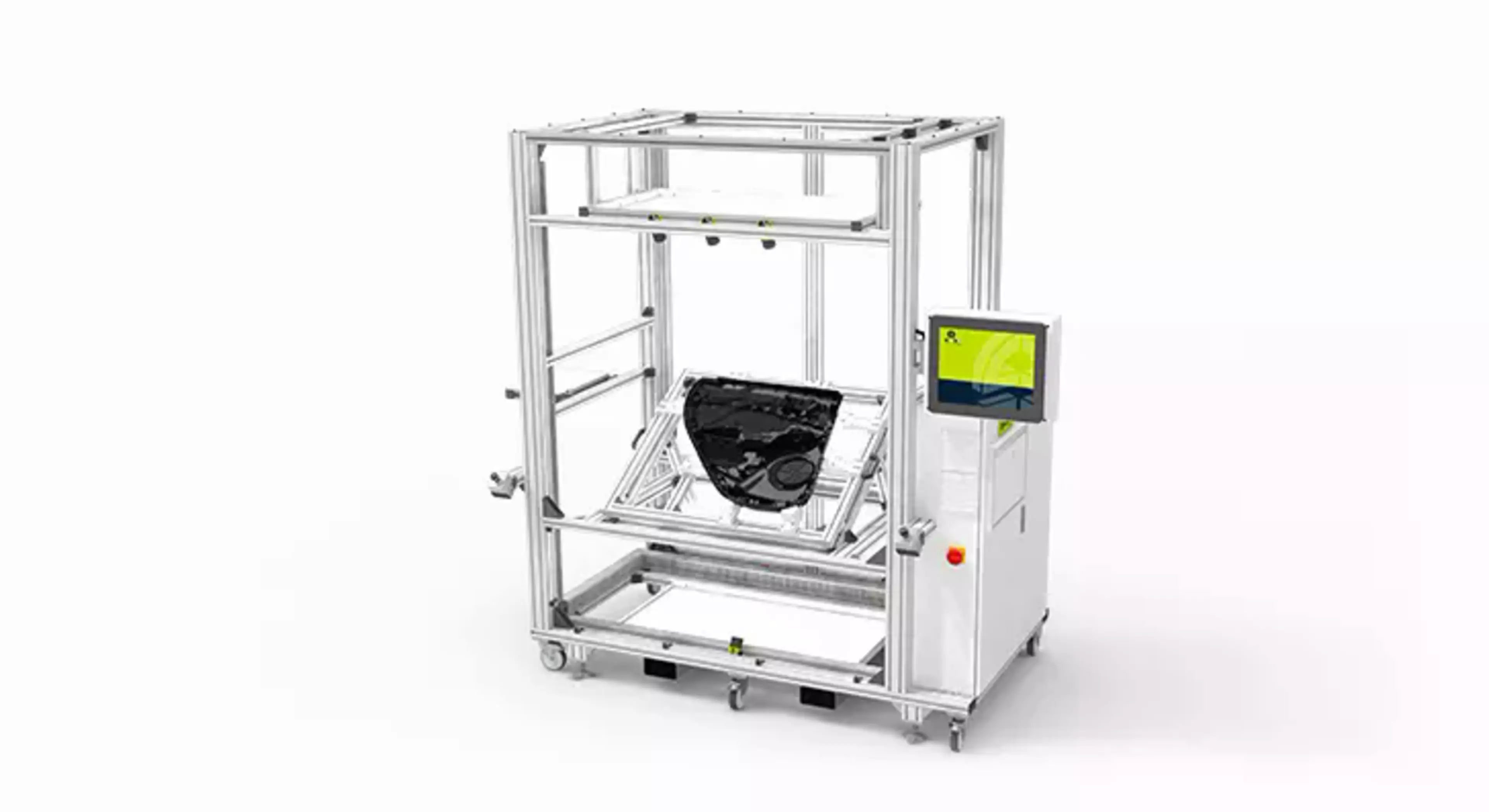

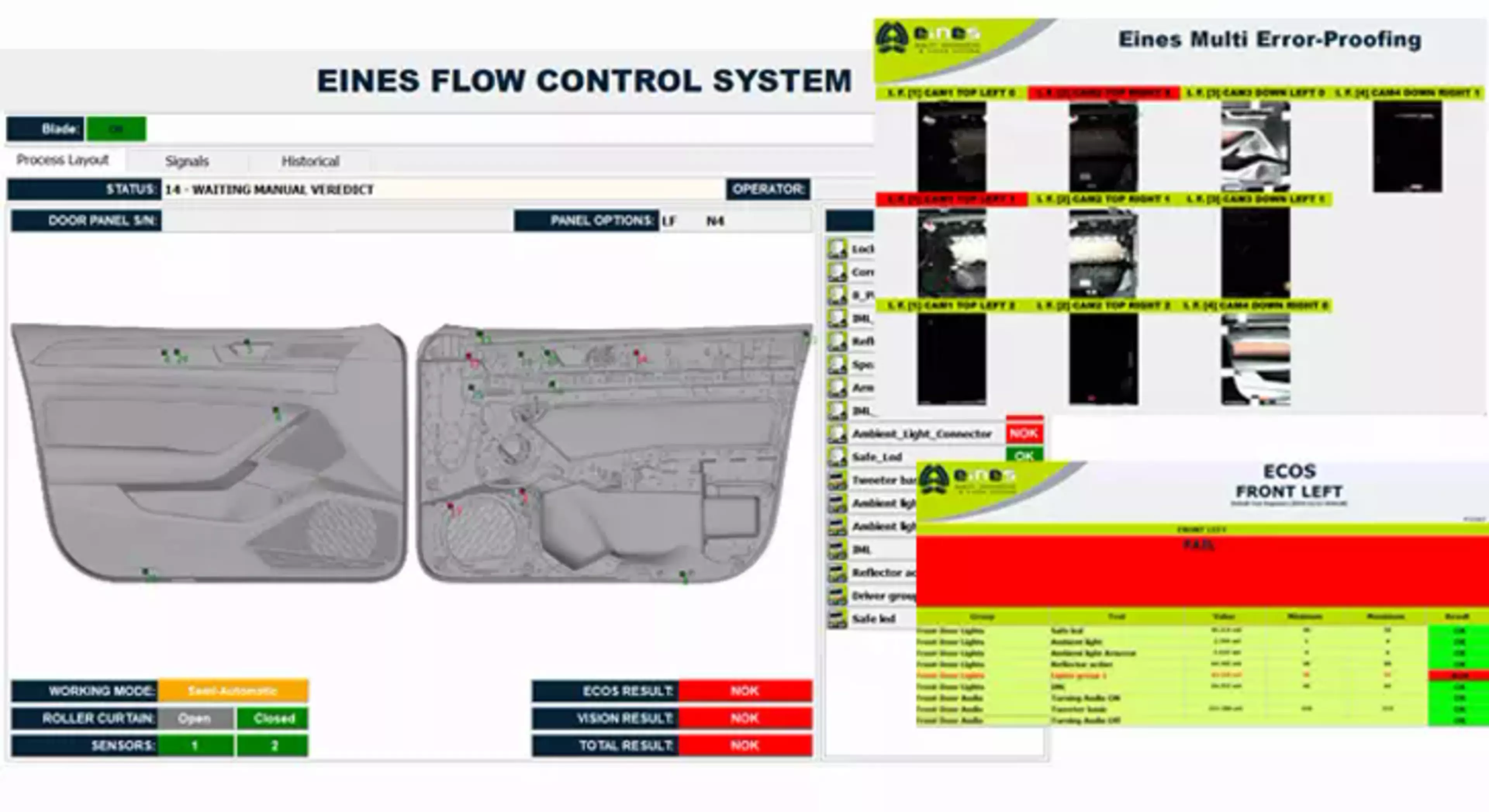

EINES Parts Check Solutions

Automotive Industry Inspection Solutions, EINES Multi Error Proofing solution for parts and components incl door panels, instrument panels and headliners.

- Door Panels Check System

- Instrument Panels Control Solution

- Multi Error Proofing Inspection for Headliners

- End of Line Tunnel System