Measurement Systems for Display Technologies used in Augmented Reality and Virtual Reality Headsets

Imaging Photometers and Imaging Colorimiters with Pupil Position AR/VR Lenses

Virtual, augmented, and mixed reality headsets deliver immersive experiences to the modern consumer, increasingly adopted into both consumer and industrial applications. Development of AR/VR and Mixed reality technologies focuses on closing the gap in image quality and improving operator immersion.

Augmented and mixed reality displays function similar to a modern Automotive HUD, projecting a virtual image onto the near eye glass. A quality display should deliver contrast, colour and uniformity across the surface.

Virtual reality displays may utilise a small display and stereoscopic lenses or a projection system which can be assessed similar to any other modern display technology, providing that the pupil position is replicated for the measurement.

Measurement of these technologies requires the ability to measure as the eye sees, using purpose-built optical technology and software that assesses the technology by replicating the human vision system from the intended pupil position. Consumer expectation for the quality of display technology is ever advancing in line with parallel technologies such as TVs and tablets.

Konica Minolta, along with group companies Radiant Vision Systems and Instrument Systems, produces a range of solutions for measuring display technology from the intended pupil position, both in development and production environments. The purpose built ARVR lens from Radiant Vision Systems ensures that near-eye-display technology delivers a high-quality user experience, in line with the consumers expectations.

Solutions will ensure control of:

- brightness,

- contrast,

- focus,

- ghosting,

- uniformity,

- image distortion,

- colour

Accurate measurement instruments will enable producers to benchmark, specify and produce with traceable data.

Traceable measurement solutions can greatly speed up development, production, and QC testing.

Our expert teams can help to implement a system that allows all parties, from component manufacturer through to final QC, to work in a more streamlined and consistent way. Experience shows that a data driven approach allows supply chains to build relationships based on quality and consistency, reducing subjectivity, and simplifying specification and approval.

Konica Minolta can deliver tested solutions to customers in the display industry through a global network of sales, support, and expertise. Our network of authorised service facilities provides ongoing maintenance and calibration of devices to minimise downtime and ensure that systems remain traceable throughout their working life.

A measurement solution from the Konica Minolta Group can ensure that you deliver a display with the right quality for the right price by helping development teams to easily and accurately characterise products from suppliers and benchmark competitors. Automated production integration will help producers to optimise takt times by implementing a measurement system that can keep pace with throughput.

Reduce production time, costs and rejects using automated inspection systems and purpose-built software that helps the production team set criteria based on accurate and traceable measurement data.

Benefits

- Improve perceived quality and deliver the quality of user interface that will exceed the consumer's expectations by developing and testing the latest technologies with the latest measurement technology to keep pace with the cutting edge of consumer electronics.

- Streamline supply and work with suppliers to develop, prototype, and test technology using trusted measurement solutions.

Instruments

Instrument Systems CAS 140D spectroradiometer

A 2D imaging colorimeter, combined with the precision of a spectroradiometer, provides accurate and fast spectral measurement as required by the “Display Specification for Automotive Application”). Spectral measurements determine the intensity of the individual colours.

Instrument Systems LumiTop AR/VR imaging colorimeter

Designed for shortest tact times within production testing of near-eye displays (NEDs), the AR/VR lens emulates the human eye, measuring colour and luminance accurately. Its unique periscope design allows easy measurement of assembled NED headsets.

Instrument Systems LumiTop X series luminance cameras

Extended sensitivity at low and high luminance ranges. It evaluates luminance, colour homogeneity, mura, pixel defects, contrast, gamma curves, white point, flicker, and luminance modulations with very short measuring times and high absolute accuracy.

Applications

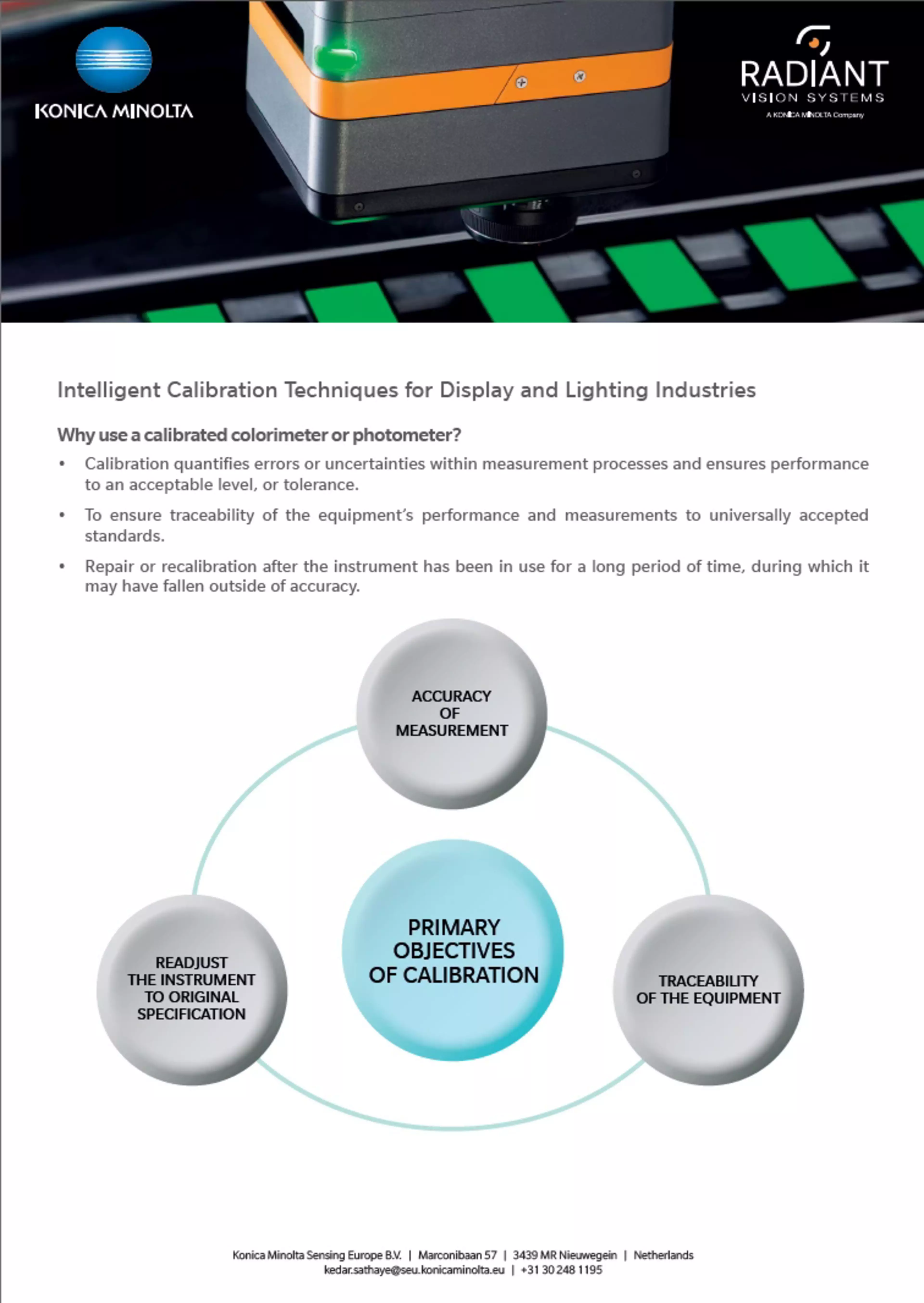

White Paper: Intelligent Calibration Techniques for LED & Display Measurement

Discover how enhanced colour calibration, adaptive multi-area corrections, and intelligent techniques improve measurement accuracy in LED and display systems. This white paper explores real-world applications and calibration benchmarks.

Download the white paper to explore calibration methods that ensure traceability and precision in light measurement instruments.

Near-Eye-Display Testing

Perfect user experience for AR/VR headsets calls for extensive, fast and highly accurate optical tests during production. In order to meet this specific challenge, Instrument Systems has developed the LumiTop AR/VR 2D imaging colorimeter. Periscopic and straight AR/VR lenses simulate the human eye and measure colour and luminance exactly as seen by the user in the already mounted headset and on modul level. TheLumiTop AR/VR lens designenables synchronised two-eye measurements, and the proven LumiTop 3-in-1 principle guarantees fast, traceable and highly accurate measurements.

Ask Our Experts